Engineering that Understands the Business

Some of the most technically “successful” projects end up becoming poor-performing assets. If you are an asset owner, PMO leader, or project director, this gap sits behind many OPEX surprises.

The drawings are correct. Standards are met. Reviews are passed. From an engineering perspective, everything looks right. Yet months or years after handover, the asset begins to disappoint as a business. Operating costs are higher than expected. Flexibility is limited. What once seemed like reasonable design decisions quietly turn into recurring operational problems.

The project is technically sound, but commercially underwhelming. And the pain is not abstract. It shows up as unplanned OPEX, reduced throughput, retrofit CAPEX, and slower payback.

This contradiction is more common than many owners would like to admit.

Why This Is Risky Today

This gap is no longer theoretical. Once an asset is built, its cost structure, risk profile, and flexibility are largely locked in. By the time problems show up in operations, it is already too late to redesign them away. At that point, the available options are usually expensive: workarounds, retrofits, downtime, or accepting higher operating costs for the next 10–20 years.

Responsibility, however, arrives later. Asset owners and operators inherit the consequences after handover, long after the design decisions that shaped those outcomes were made. What feels like an operational problem is often the delayed result of choices taken years earlier, when the priority was making the design work.

As assets become more complex and margins tighter, the cost of this disconnection becomes more visible, and harder to absorb.

When Business Intent Loses Ownership

At the start of most projects, business intent is clearly discussed. Cost targets, risk trade-offs, operational priorities, and value expectations are shaped early during feasibility and planning.

But as projects move into conceptual, schematic, and detailed design, something subtle often happens.

Business intent no longer has a clear owner. The people now driving decisions (client representatives, engineering consultants, technical leads, and specialists) were often not part of those early discussions. They enter the project with a clear mandate: deliver a compliant, coordinated, technically robust design.

Naturally, they do exactly that.

Decisions are optimised for safety, performance, standards, and constructability. What often sits outside this decision framework are downstream business consequences: operating cost sensitivity, flexibility under changing use, long-term risk exposure, or how quickly value can actually be realised.

Individually, each decision makes sense. Collectively, they hard-wire the business performance of the asset long before operations begin.

Business intent may still exist in reports and briefing documents. But without a role or mechanism that actively brings it into everyday design conversations, it stops being tested. Not because teams don’t care about the business, but because the project no longer asks them to.

The Gap Is Not Engineering Execution

This is not a story about poor engineering.

In many projects, the engineering work is competent, rigorous, and delivered exactly as intended. The gap lies not in execution, but in how engineering decisions are framed, tested, and judged.

Design choices are reviewed for technical correctness, coordination, and constructability. They are not consistently tested against business outcomes. As a result, design decisions can be “correct” while quietly increasing lifecycle cost, locking in future maintenance burden, or reducing operational throughput.

Engineering is doing its job well. What is missing is a decision framework that treats business impact as a first-class test, not an implicit assumption.

Engineering Decisions as Business Commitments

A different outcome emerges when engineering decisions are framed differently at the moment they are made.

Beyond asking whether a solution is technically correct, the decision is also tested against its business consequences: lifecycle cost exposure, operational risk, future adaptability, and how the asset is expected to create value.

This is not an added scope or a new layer of process. It is a shift in professional judgement. Technical soundness remains essential, but it is no longer treated as the finish line. Engineering choices are recognised for what they are: long-term commitments that shape cost, risk, and flexibility well beyond construction.

Consider a common example from distressed infrastructure. When clients face cracked structures, damaged slabs, or recurring failures, engineers can always calculate a technically sound strengthening solution. The difference appears when the problem is framed through a business lens. How is the asset actually being used? What load patterns, operating cycles, or commercial pressures caused the issue?

A solution calibrated to those realities does more than fix a structure. It protects long-term value. In many cases, the business impact is far greater than the defect itself: downtime, safety restrictions, temporary closures, tenant disruption, and emergency works often cost far more than the repair.

The engineering remains rigorous. The difference lies in how the solution is framed, tested, and justified.

Why This Has Become a Leadership Issue

Today, the margin for “technically fine” is disappearing. Assets must remain viable, adaptable, and economically defensible over time. Once engineering decisions are locked into design, their business consequences are difficult and expensive to undo.

For asset owners and business leaders, this creates a clear distinction. Some engineering advice closes technical risks. Others actively protect long-term value. Treating them as equivalent is no longer harmless.

The question is no longer whether engineering is done correctly, but whether it is being judged against the outcomes the business actually depends on. That distinction is becoming a strategic advantage for those who recognise it early, and a silent liability for those who don’t.

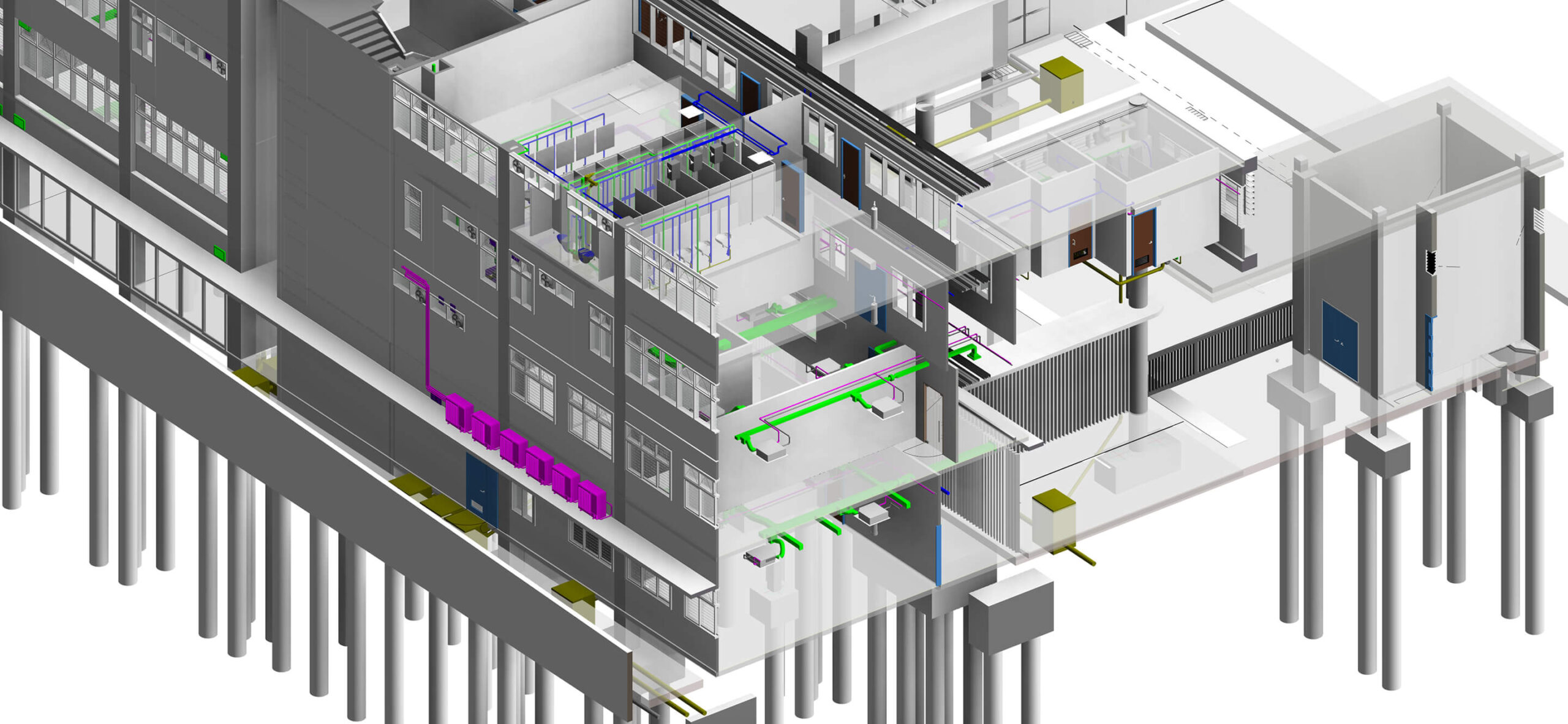

Ivana Sadikin is a Pinion co-founder advancing BIM as an information framework and digital transformation to enable structured data environments and lifecycle-driven project intelligence.